Pensa Labs DIWire

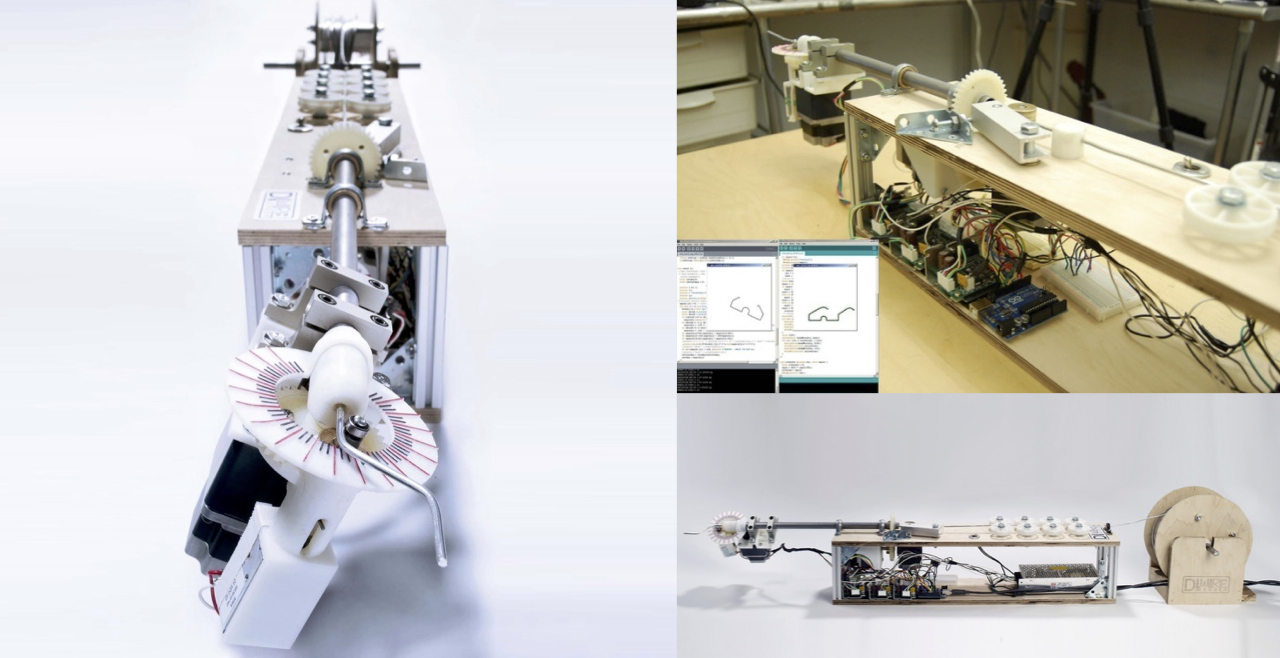

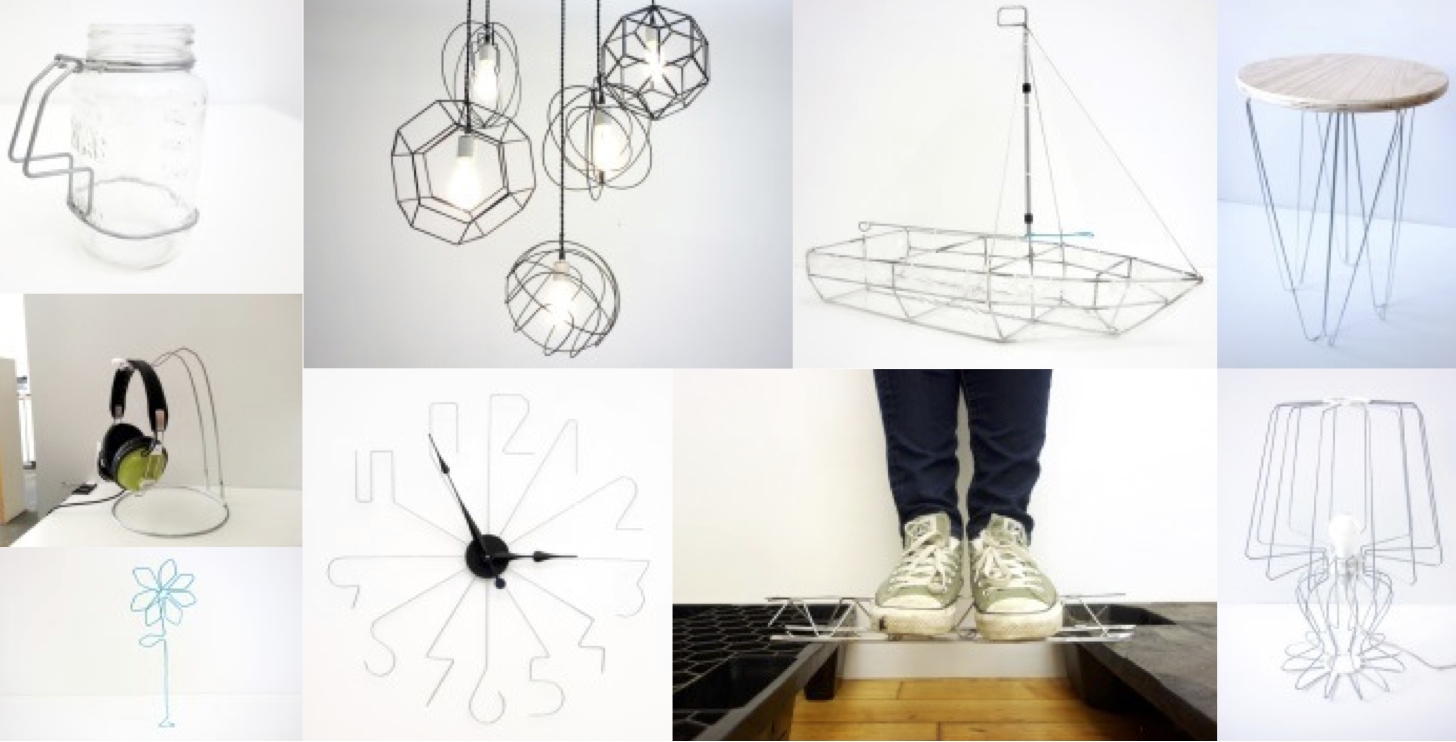

The DIWire Bender is the first desktop CNC wire bender. A new archetype for desktop manufacturing and rapid prototyping, the DIWire transforms drawn curves into bent wire that can be assembled to make just about anything.

To date, desktop manufacturing has focused on 3D printers outputting plastic volumes and laser cutters cutting 2D planes. However, nothing exists that converts lines into bent rod, wire or tubular forms quickly, accurately, and repeatably. The DIWire can bend metals and plastics of various diameter.

DIWire was the winner of the 2013 Engadget Insert Coin Award, MakerFaire Editors Choice Blue Ribbon Award, DUMBO Dozen Award, and reached its Kickstarter goal on the very first day of the campaign.

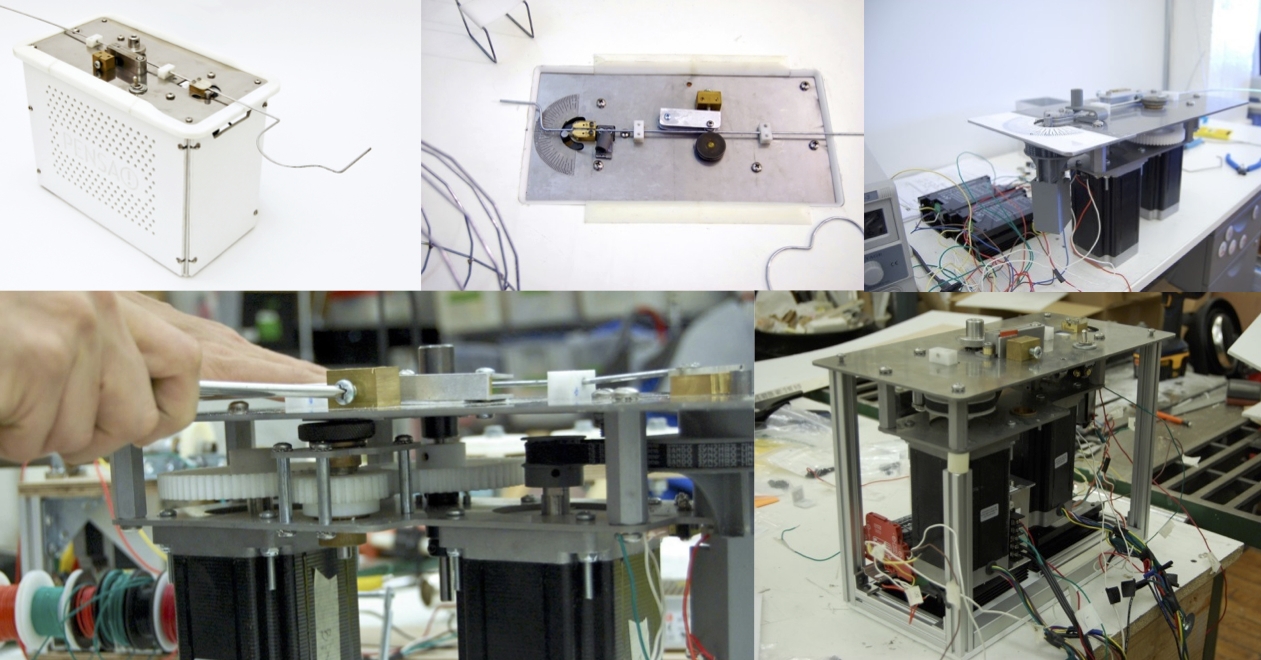

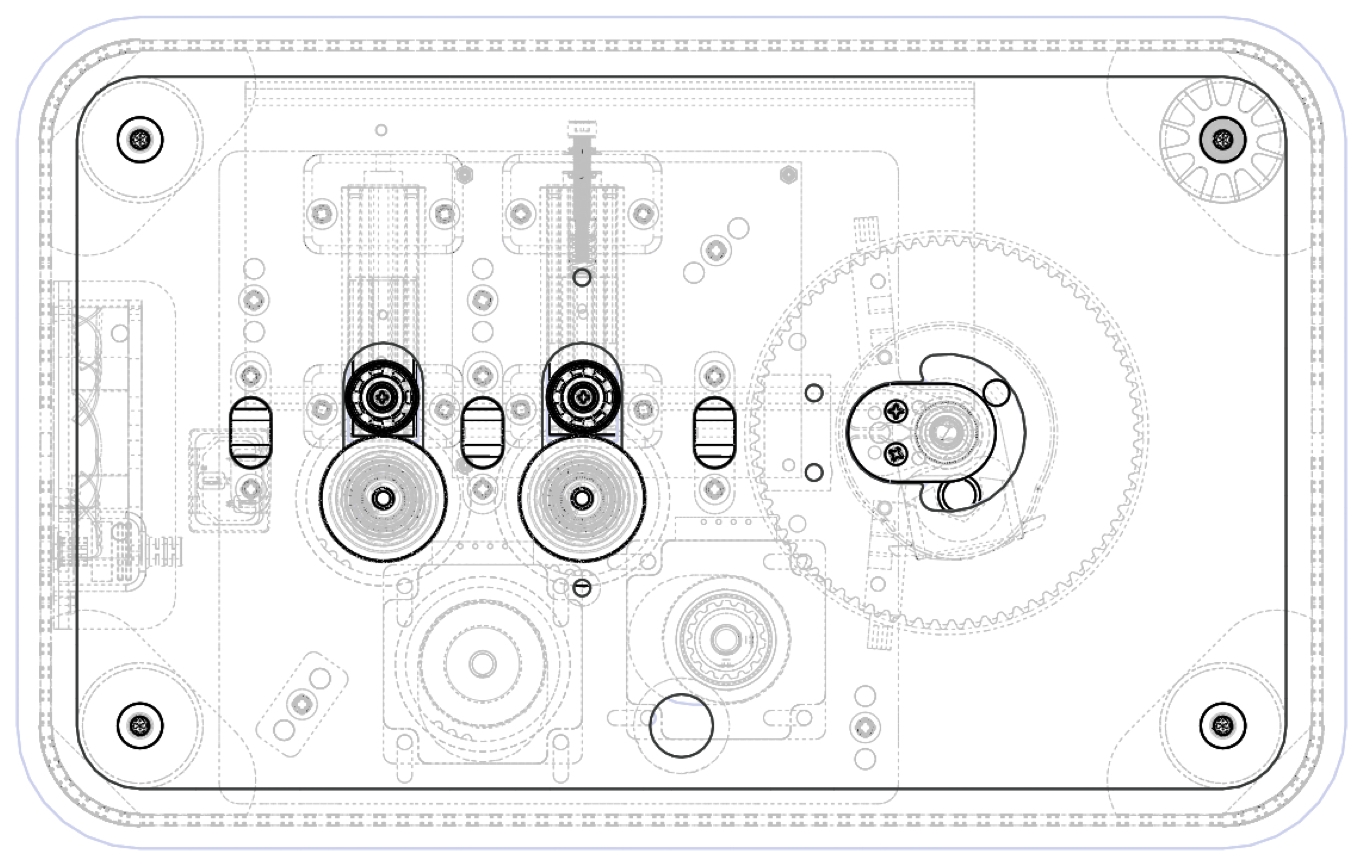

• Key contributor to mechanical, electrical, and software aspects of product development

• Wrote code that converts drawn curves into motor motion

• Heavily involved with the design, testing, and construction of DIWire 1.0 and 2.0

• Developed belt drive system and adjustable feed wheels

• Utilized CNC machining skills to test bend head designs

• Assisted in workshops, demos, and fairs to educate the public about the product

• Assisted in assembly of beta test units

• Design challenges included calibration, repeatability, cycle testing, and a robust design for high motor torque